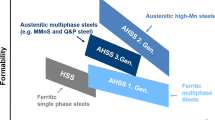

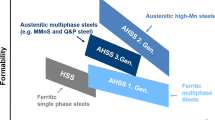

Development of Advanced High-Strength Steels for Automobile Applications

Stelco has developed a suite of Advanced High-Strength Steels (AHSS) grades with tensile strength greater than 1000 MPa to meet standard automotive specifications and for unique customer requirements. These grades were optimized by correlating chemical composition and processing parameters with microstructures and mechanical properties . Dual-Phase 980 (Stelco trademarked STELMAX TM 980DP), Multiphase 1180 (STELMAX TM 1180MP), Martensitic 1300 (STELMAX TM 1300M) and 1500 (STELMAX TM 1500M) products met strength and formability requirements with excellent flatness and consistent mechanical properties across the entire strip length and width by using hydrogen quench continuous annealing technology.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

eBook EUR 287.83 Price includes VAT (France)

Hardcover Book EUR 369.24 Price includes VAT (France)

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Advanced High-Strength Sheet Steels for Automotive Applications

Chapter © 2021

Newly Developed Advanced High Strength Steels for Automotive Lightweight Applications

Chapter © 2016

Materials and Processes for the Third-generation Advanced High-strength Steels

Article 02 October 2019

References

- Keeler S, Kimchi M (2014) Advanced high strength steels application guidelines version 5.0, pp 1–276. http://www.autosteel.org

- Chatterjee D (2017) Behind the development of advanced high strength steel (AHSS) including stainless steel for automotive and structural applications—an overview. Mater Sci Metall Eng 4(1):1–15 Google Scholar

- Osawa K, Suzuki Y, Tanaka S (2003) TS590 980 grade low-carbon equivalent type galvannealed sheet steels with superior spot-weldability. Kawasaki Steel Technical Report, No. 48 Google Scholar

- Krauss G (1999) Martensite in steel: strength and structure. Mater Sci Eng A 273–275:40–57 ArticleGoogle Scholar

- Mohrbacher H (2014) Martensitic automotive steel sheet—fundamentals and metallurgical optimization strategies. NiobelCon bvba, Schilde, Belgium BookGoogle Scholar

- Zhou T, Overby D, Badgley P, Martin-Root C, Wang X, Liang SL, Zurob H (2018) Study of processing, microstructure and mechanical properties of hot rolled ultra high strength steel. Ironmak & Steelmak. https://doi.org/10.1080/03019233.2018.1468652

- Martin JW, Doherty RD, Cantor B (1997) Stability of microstructure in metallic systems, 2nd edn. Cambridge university Press, Cambridge BookGoogle Scholar

- Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier Ltd., Oxford, UK Google Scholar

- Blankenau MR, Slack M, Brenninger M (2017) Performance characteristics of HyCAL toll continuous annealing facility. AIST, pp 243–251 Google Scholar

- Oliver S, Jones TB, Fourlais G (2007) Dual phase versus trip strip steels: microstructural changes as a consequence of quasi-static and dynamic tensile testing. Mater Charact 58(4):390–400 ArticleCASGoogle Scholar

Acknowledgements

The authors acknowledge Mr. Mark Blankenau at HyCal Corporation (Gibraltar, MI, USA), Ironmaking and Steelmaking Operation, Hot Strip Mill Operation, Cold Mill Operation and Quality Assurance Department at Stelco Inc. (Hamilton and Nanticoke, ON, Canada).

Author information

Authors and Affiliations

- Research Department, Stelco Inc., 386 Wilcox Street, Hamilton, ON, L8L 8K5, Canada Francys Barrado, Tihe Zhou, David Overby, Peter Badgley, Chris Martin-Root, Sarah Zhang & Rich Zhang

- Francys Barrado